New Rubber Roller Cutting and Grinding Machine

Payment Type: L/C,T/T,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW

Min. Order: 1 Set/Sets

Delivery Time: 40 Days

Transportation: Ocean

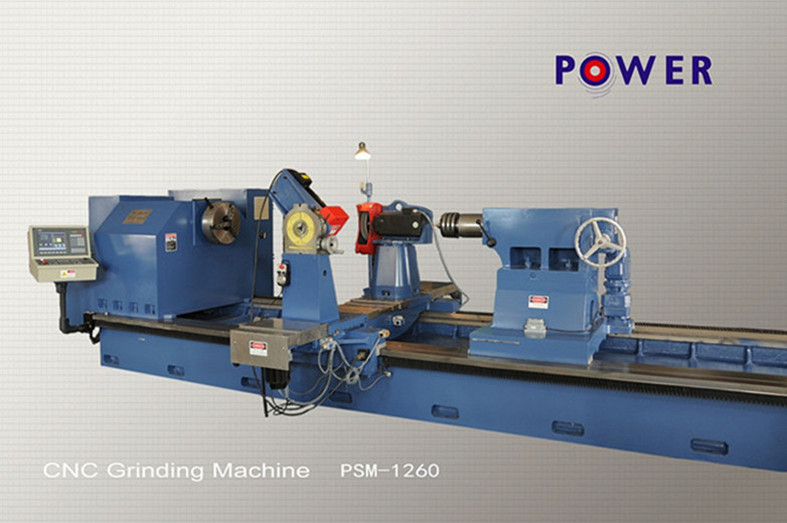

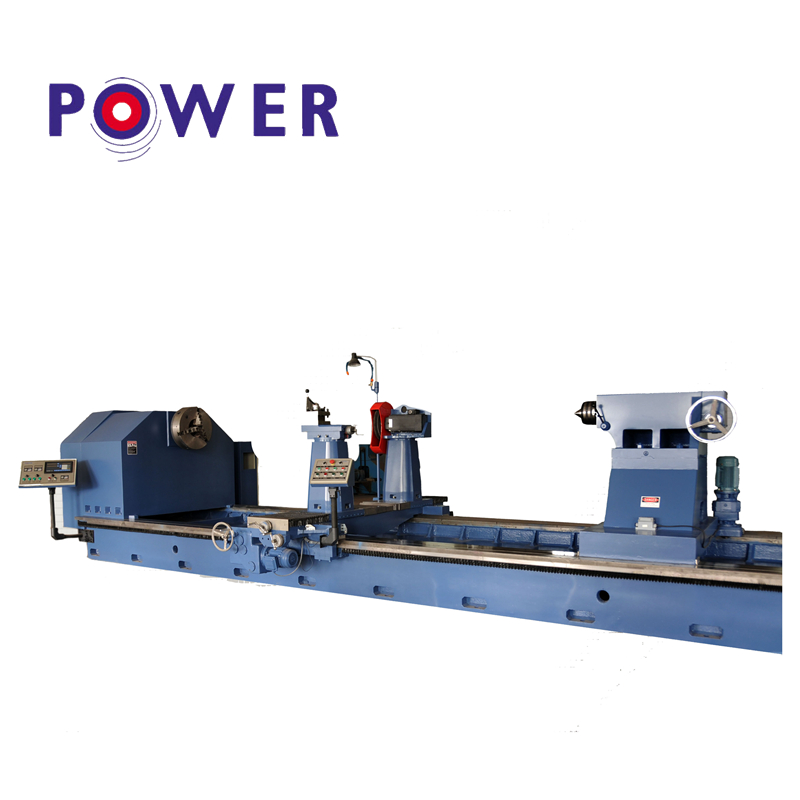

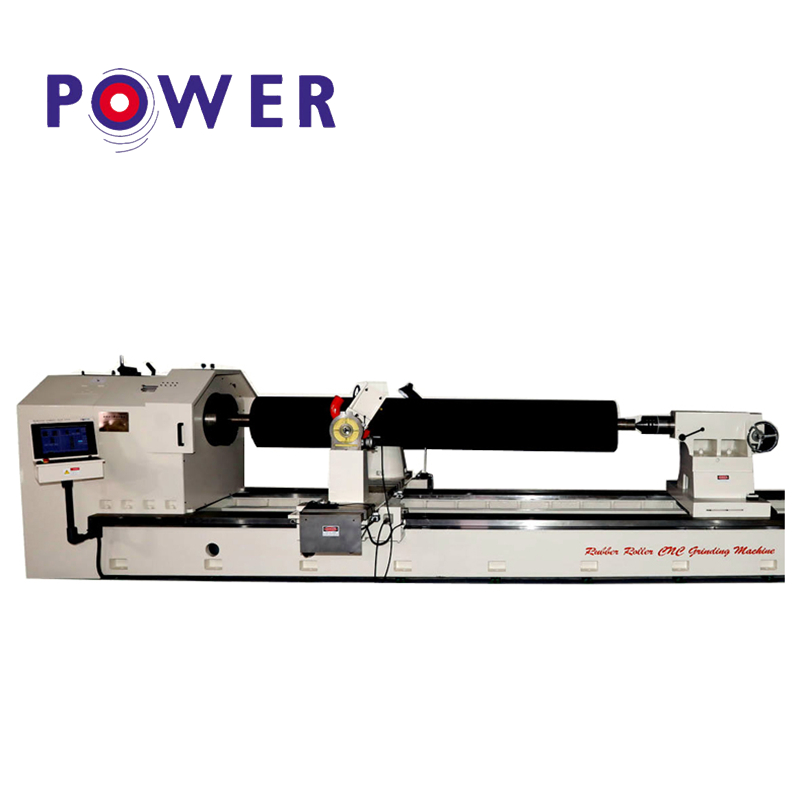

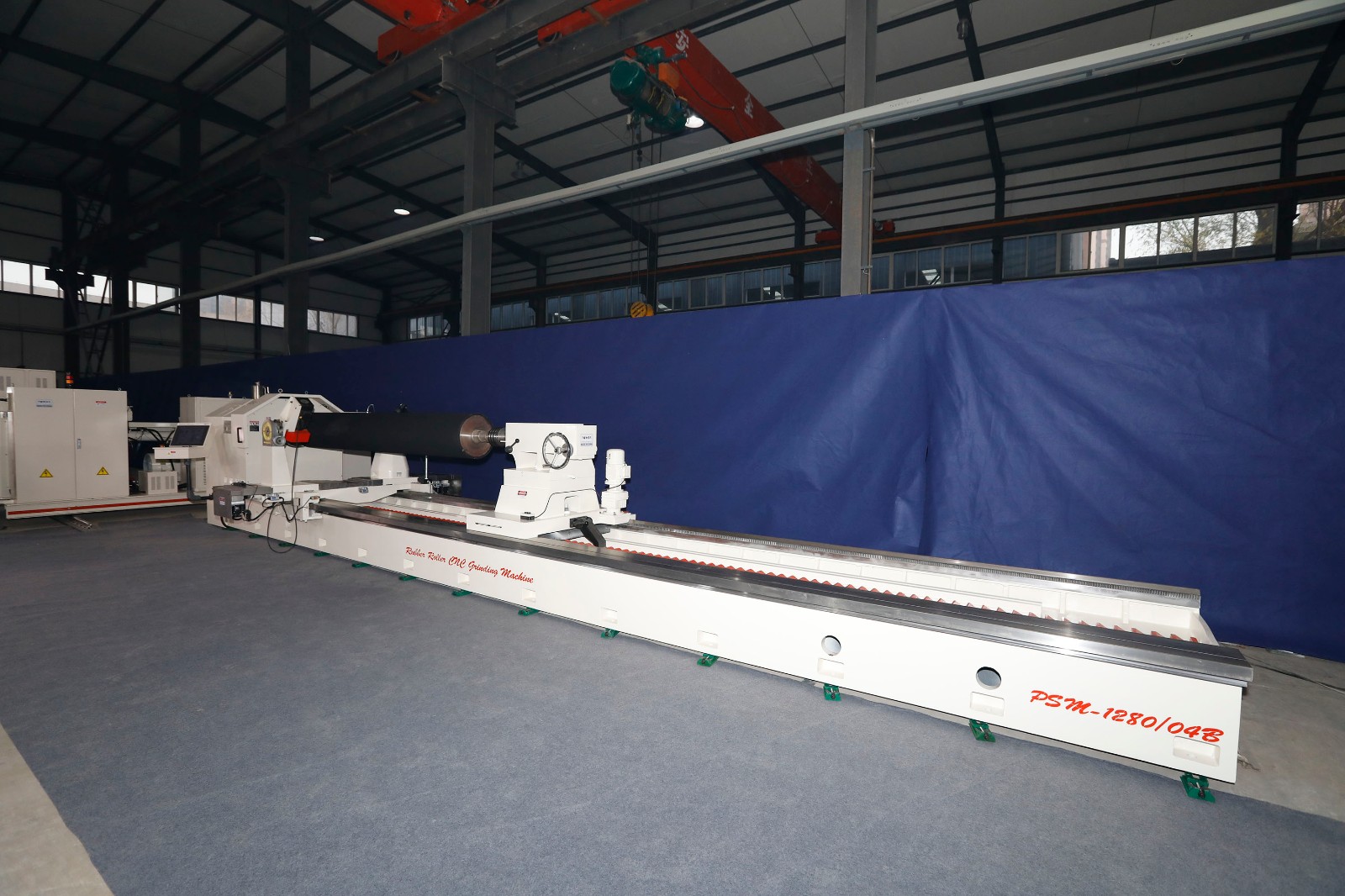

Factory Rubber Roller Grinding Machine For Textile The characteristic of PSM collection manufacturing facility rubber curler grinding device for fabric 1 Standard system of PSM collection consists of a a complete flood recirculating coolant machine b motorized tailstock c variable pace traverse and spindle drives d the front and rear independently.

The feature of PSM series factory rubber roller grinding machine for textile

1. Standard equipment of PSM series includes:

a. a full flood recirculating coolant system

b. motorized tailstock

c. variable speed traverse and spindle drives

d. front and rear independently operated carriage tables

e. a direct drive grinding head mounted on the rear

2. Specially designed to replace the tradtional roller grinding process method.

3. Two medium carriage tables assembled to ensure accurate performance and operating stability.

4. The max. linear speed of grinding head is over 90m/s. Production efficiency is highly increased and the geometric size is guaranteed.

5. Advanced measuring device assembled timely checks the processing datas and provides effective help to control the grinding size.

6. Capable of realizing expansion of processing of special-shaped Rubber Rollers.

MODEL | SPECIFICATION | MAX. DIAMETER | MAX. LENGTH | CUBAGE | POWER |

LIGHT SCALE | PSM-4020-CNC | 16" 400mm | 80" 2000mm | 158"*63"*55" 4m*1.6m*1.4m | 17KW |

STANDARD | PSM-8040-CNC | 32" 800mm | 158" 4000mm | 256"*71"*63" 6.5m*1.8m*1.6m | 22KW |

HEAVY DUTY | PSM-1260-CNC | 47" 1200mm | 236" 6000mm | 315"*79"*71" 8.0m*2.0m*1.8m | 26KW |

LARGE SCALE | PSM-1680-CNC | 63" 1600mm | 315" 8000mm | 433"*95"*71" 11m*2.4m*1.8m | 32KW |

PSM series factory rubber roller grinding machine for textile is specially designed and manufactured to replace the past roller processing method by metallic manufacturing equipment. Mounted grinding head on the engine lathe is the past method to manufacture roller, which the quality of roller is difficult to reach the requirement of the present standard. The main reason lies in the structure of lathe. After all, it is not the grinding machine; the moving spaces of the big and medium carriage table are larger than that of grinding machine. Therefore, vibration may be produced while in the grinding processing, which will generate ripple at the surface of processing rollers. Further, due to the width limit of the guide-rail of lathe, the way of mounted grinding head is hardly to ensure the stability while in operation.

Packaging & Shipping

Packing details:

1. Outside package: Standard export wooden cases

2. Inner package: Stretch film

Shipping detail:

Within 2-4 weeks

Equipment video:

Shipping photos :

Related News

Submitted successfully

We will contact you as soon as possible