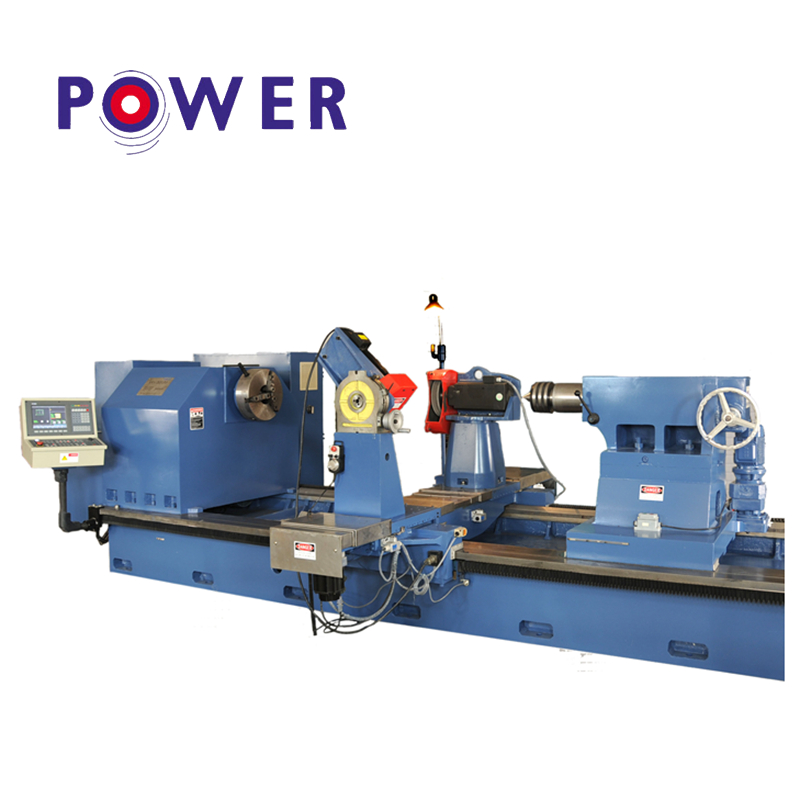

Grinding Machine for Rubber Roller Processing

The function of PSM series grinding computer for rubber roller processing

1. Standard gear of PSM series includes:

a. a full flood recirculating coolant system

b. motorized tailstock

c. variable velocity traverse and spindle drives

d. front and rear independently operated carriage tables

e. a direct power grinding head mounted on the rear

2. Specially designed to substitute the tradtional roller grinding system method.

3. Two medium carriage tables assembled to ensure correct performance and running stability.

4. The max. linear speed of grinding head is over 90m/s. Production effectivity is highly expanded and the geometric size is guaranteed.

5. Advanced measuring machine assembled timely assessments the processing datas and provides fantastic help to manage the grinding size.

6. Capable of realizing expansion of processing of special-shaped Rubber Rollers.

MODEL | SPECIFICATION | MAX. DIAMETER | MAX. LENGTH | CUBAGE | POWER |

LIGHT SCALE | PSM-4020-CNC | 16" 400mm | 80" 2000mm | 158"*63"*55" 4m*1.6m*1.4m | 17KW |

STANDARD | PSM-8040-CNC | 32" 800mm | 158" 4000mm | 256"*71"*63" 6.5m*1.8m*1.6m | 22KW |

HEAVY DUTY | PSM-1260-CNC | 47" 1200mm | 236" 6000mm | 315"*79"*71" 8.0m*2.0m*1.8m | 26KW |

LARGE SCALE | PSM-1680-CNC | 63" 1600mm | 315" 8000mm | 433"*95"*71" 11m*2.4m*1.8m | 32KW |